看它顏色很清透,一般塑膠材質好像不容易這麼亮,如果是玻璃那輕輕碰撞到不就容易破裂了

totoh wrote:

看它顏色很清透,一...(恕刪)

13-high-performance-plastics-used-in-the-automotive-industry:

剛剛查了一下 大約有13種高性能塑膠用在汽車工業。

第10的 Acrylic (PMMA)丙烯酸;壓克力---> 是有可能的

只是我們一般看到的壓克力是廣告業在用的,工業上用可以加其他的化學配方讓他更透明與堅固。

家電業常用的ABS塑膠也是一樣,有許多種。

http://www.craftechind.com/13-high-performance-plastics-used-in-the-automotive-industry/

Here are the top 13 high performance plastics used in automotive hardware. While all 13 may easily be used in a single vehicle, just three types of plastic make up approximately 66% of the total high performance plastics used in a car: polypropylene (32%), polyurethane (17%) and PVC (16%).

1) Polypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications. A saturated addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

Application: automotive bumpers, chemical tanks, cable insulation, gas cans, carpet fibers.

2) Polyurethane (PUR)

Solid Polyurethane is an elastomeric material of exceptional physical properties including toughness, flexibility, and resistance to abrasion and temperature. Polyurethane has a broad hardness range, from eraser soft to bowling ball hard. Other polyurethane characteristics include extremely high flex-life, high load-bearing capacity and outstanding resistance to weather, ozone, radiation, oil, gasoline and most solvents.

Application: flexible foam seating, foam insulation panels, elastomeric wheels and tires, automotive suspension bushings, cushions, electrical potting compounds, hard plastic parts.

3) Poly-Vinyl-Chloride (PVC)

PVC has good flexibility, is flame retardant, and has good thermal stability, a high gloss, and low (to no) lead content. Polyvinyl chloride molding compounds can be extruded, injection molded, compression molded, calendered, and blow molded to form a huge variety of products, either rigid or flexible depending on the amount and type of plasticizers used.

Application: automobile instruments panels, sheathing of electrical cables, pipes, doors.

4) ABS

Acrylonitrile Butadiene Styrene is a copolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The styrene gives the plastic a shiny, impervious surface. The butadiene, a rubbery substance, provides resilience even at low temperatures. A variety of modifications can be made to improve impact resistance, toughness, and heat resistance.

Application: automotive body parts, dashboards, wheel covers.

5) Polyamide (PA, Nylon 6/6, Nylon 6)

Nylon 6/6 is a general-purpose nylon that can be both molded and extruded. Nylon 6/6 has good mechanical properties and wear resistance. It is frequently used when a low cost, high mechanical strength, rigid and stable material is required. Nylon is highly water absorbent and will swell in watery environments.

Application: gears, bushes, cams, bearings, weather proof coatings.

6) Polystyrene (PS)

Naturally clear, polystyrene exhibits excellent chemical and electrical resistance. Special high gloss and high impact grades are widely available. This easy to manufacture plastic has poor resistance to UV light.

Application: equipment housings, buttons, car fittings, display bases.

7) Polyethylene (PE)

Polyethylene has high impact resistant, low density, and exhibits good toughness. It can be used in a wide variety of thermoplastics processing methods and is particularly useful where moisture resistance and low cost are required.

Application: car bodies (glass reinforced), electrical insulation.

8) POM (polyoxymethylene)

POM has excellent stiffness, rigidity, and yield strength. These properties are stable in low temperatures. POM also is highly chemical and fuel resistant.

Application: interior and exterior trims, fuel systems, small gears.

9) Polycarbonate (PC)

Amorphous polycarbonate polymer offers a unique combination of stiffness, hardness and toughness. It exhibits excellent weathering, creep, impact, optical, electrical and thermal properties. Because of its extraordinary impact strength, it is the material for car bumpers, helmets of all kinds and bullet-proof glass substitutes.

Application: bumpers, headlamp lenses.

10) Acrylic (PMMA)

A transparent thermoplastic, PMMA is often used as a lightweight or shatter-resistant alternative to glass. It’s cheaper than PC but is also more prone to scratching and shattering.

Application: windows, displays, screens.

11) PBT (polybutylene terephthalate)

The thermoplastic PBT is used as an insulator in the electrical and electronics industries. It is highly chemical and heat resistant. Flame-retardant grades are available.

Application: door handles, bumpers, carburetor components.

12) Polyethylene Teraphthalate (PET)

PET is mostly used to create synthetic fibers and plastic bottles. You may recognize it on clothing labels under the name “polyester.”

Application: wiper arm and gear housings, headlamp retainer, engine cover, connector housings.

13) ASA (acrylonitrile styrene acrylate)

Similar to ABS, ASA has great toughness and rigidity, good chemical resistance and thermal stability, outstanding resistance to weather, aging and yellowing, and high gloss. Be careful not to burn this material. It will cause a toxic smoke.

soziohall wrote:

13-high-performance...(恕刪)

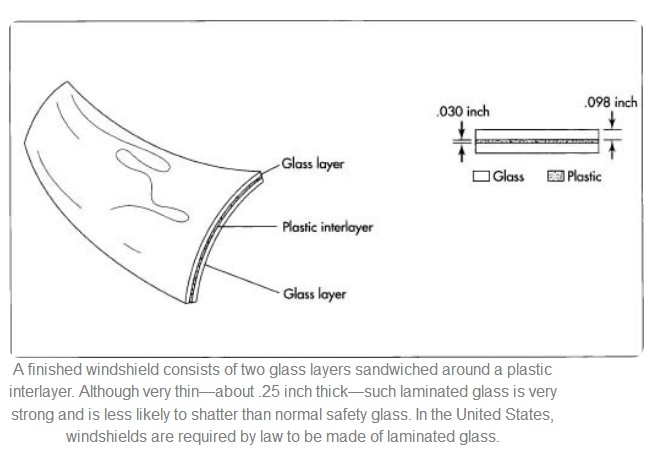

順便補充一下 汽車玻璃

基本上有兩片玻璃中間有夾層塑膠。

好壞就在玻璃的品質與夾層塑膠。

高價車當然有特殊的加料。

Laminated glass (層狀玻璃)

Laminated glass is a type of safety glass that holds together when . In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA), between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass. In the case of the EVA, the thermoset EVA, offers a complete bounding (cross-linking) with the material whether it is glass, polycarbonate, P.E.T. or other types products.

內文搜尋