與大師的全程D檔半離合生熱, 熱量透過: 1. 變速箱外殼---潤滑油---到電腦 或是 2.:離合器--- 離合器推桿--- 閥體/閥體油---電腦, 有著顯著的不同!

先駁斥大師見解: 1. 路徑面積過大,熱量未達電腦之前,已經由廣大散熱面積散去。 2. 傳導僅經由兩根離合器挺桿傳遞,路徑過小,無法有效傳遞足夠熱量到達電腦。 況且,挺桿前端都有橡皮緩衝震動與異音。 也因此,熱量被橡膠大量阻隔。

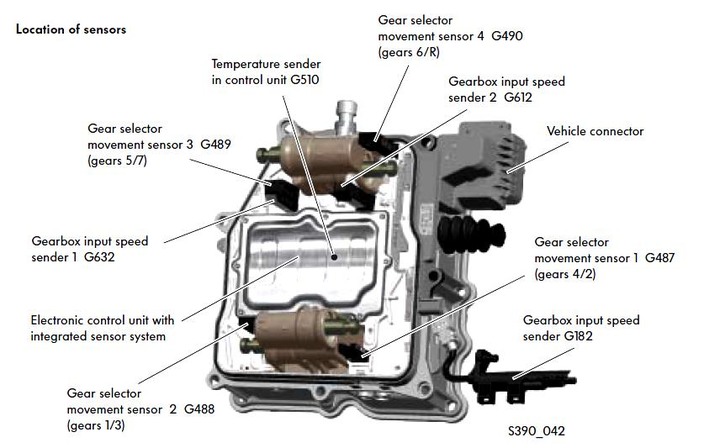

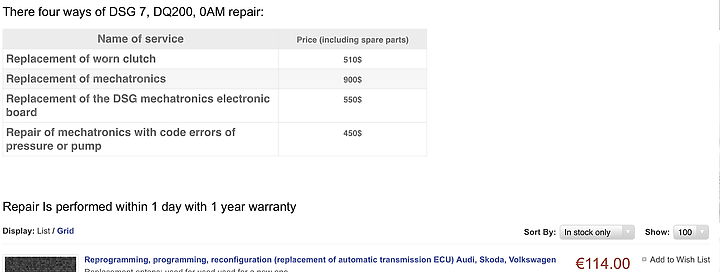

網頁貼圖

以下針對網頁文字來做翻譯:

DSG 7 0AM or DQ200 - are different names for robotised gearboxes with two dry clutches that are mounted on some Volkswagen vehicles. It is necessary to replace the gear oil of DSG7 in the amount of 1.7 liters. At the same time, there are no check plugs, oil filling in DSG 7 is strictly dosed.

DSG 7 0AM 或是 DQ200 - 是配備在一些福斯車輛,乾式雙離合器自動化變速箱的不同稱呼。 DSG7 是必須更換1.7公升的齒輪油。 同時,沒有檢視插塞,DSG 7 的注油是嚴格計量的!

0AM problems are most often associated with two units a clutch and mechatronics. Together with significant wear of the dual clutch, the mechatronic pump operates without stopping to ensure the maximum output of the clutch release rod. This leads to overheating of the mechatronics electronic unit and fusing of the insulation of the pump contacts.

0AM的多種毛病,通常與兩個單元相關: 離合器單元與機電控制單元。 當雙離合器片磨損到重大程度,加上機電泵浦打個不停,以確保離合器挺桿的最大輸出的情況之下,這樣可以導致機電電子單元的過熱, 並將泵浦電插頭的絕緣融化!

The solution of this problem is replacing the electronic board with subsequent programming. The specialists of «Maktrans» can program the software in the empty electronic block both on the car and without it. It is very important to understand that a short circuit inside the electronic control unit (ECU) does not happen by accident, there are grounds for this. The next reason after the worn-out clutch is the hydraulic leak inside the DSG 7 mechatronics. The understanding of the problem, and the fact that you are a victim of German technical progress comes in the form of a flashing signal on the instrument panel, and an eternally wet mechatronic breather. The electric motor of the pump does not stop after switching on the ignition, it buzzes constantly. If you do nothing, the car will soon stop. There are two ways to solve the problem - replacing mechatronics or replacing the casing with a crack for a new one with a 1 year warranty (weld seam on the crack is also cracking). And the most terrible thing that can occur while driving is the pressure sensor failure. In this case, the pressure in the system rises until the hydraulic accumulator fires forward. After that, the car stops and you have to wait for the tow truck.

這個問題的解決方式,是更換電子電路板(電腦)以及隨後的軟體裝設。 «Maktrans»的技師能夠在車上,或是不在車上,幫空白電腦灌程式。 了解到電子控制單元(ECU)的內部短路,並不是偶發事件,是很重要的! 這是有發生的背景的。 在離合器磨完之後的下一個原因,便是機電單元的液壓油內漏。從儀表板閃爍的燈號以及機電單元機電單元上,永遠油濕不乾的通風口,就可以了解到問題的存在,以及你是如何成為德國技術進程的犧牲者! 泵浦的電動馬達,自從開紅火之後,就打個不停。 它不斷的嗡嗡叫! 如果你不處理,這車不久之後就會停擺。 兩個方式來解決問題: 更換機電單元,或是把裂掉的鑄件換新(一年保固。 焊接裂縫還是會裂)。 並且,行駛中能發生的最糟糕事件,就是壓力感知器故障。 這種情況下,系統壓力會上升,直到蓄壓器射出脫離! 在此之後,這車立刻拋錨,你就必須等拖吊卡車了!

https://maktrans.net/remont-akpp/dsg-7

結論:

跟大師一樣! 有點唬爛! 我不是贊同全部的觀點! 有點為了生意,來嚇唬人! 例如,壓力感知器壞了,壓力就會上升至爆閥體? 我不相信! 因為還有機械式的 洩壓閥保護著系統!

但是,某一觀點,卻開啟了不同視野! 原來電動馬達打個不停,是可能傷電腦的! 因為馬達跟電腦,就只有一牆之隔! 鄰居著火了,只要火夠大,出事的機會就大! 然而,腦補跟事實,往往有距離。 就是不知道這距離有多大。

大師的全程D檔,離合器生熱, 要傳到電腦, 就像是巷口火警要燒到巷尾! 機會超小!

有趣的觀點,特來分享! 我不打包票這觀點! 認為有沒有可能,大家自由心證!